| General Capabilities |

Design & Concept Consulting |

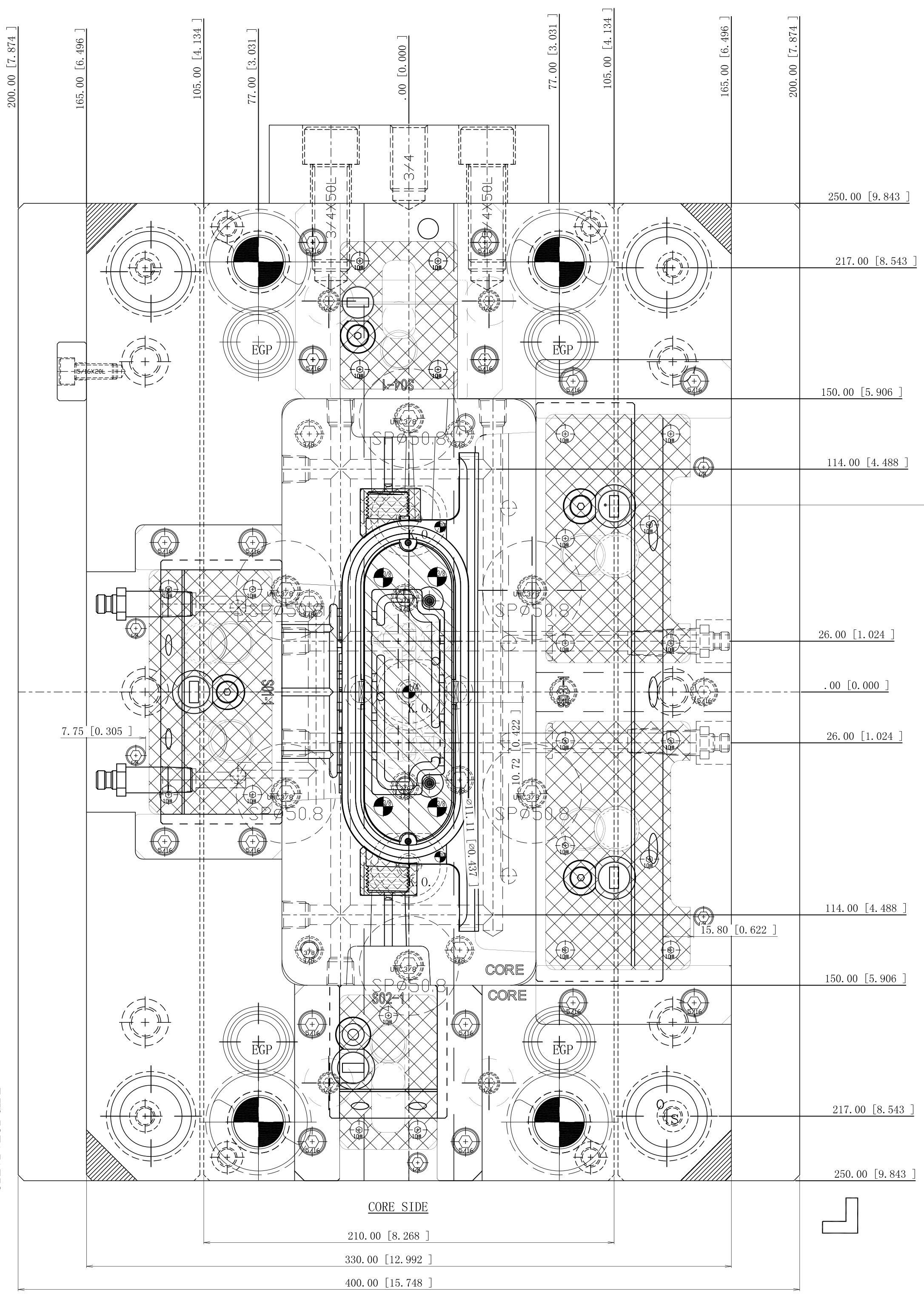

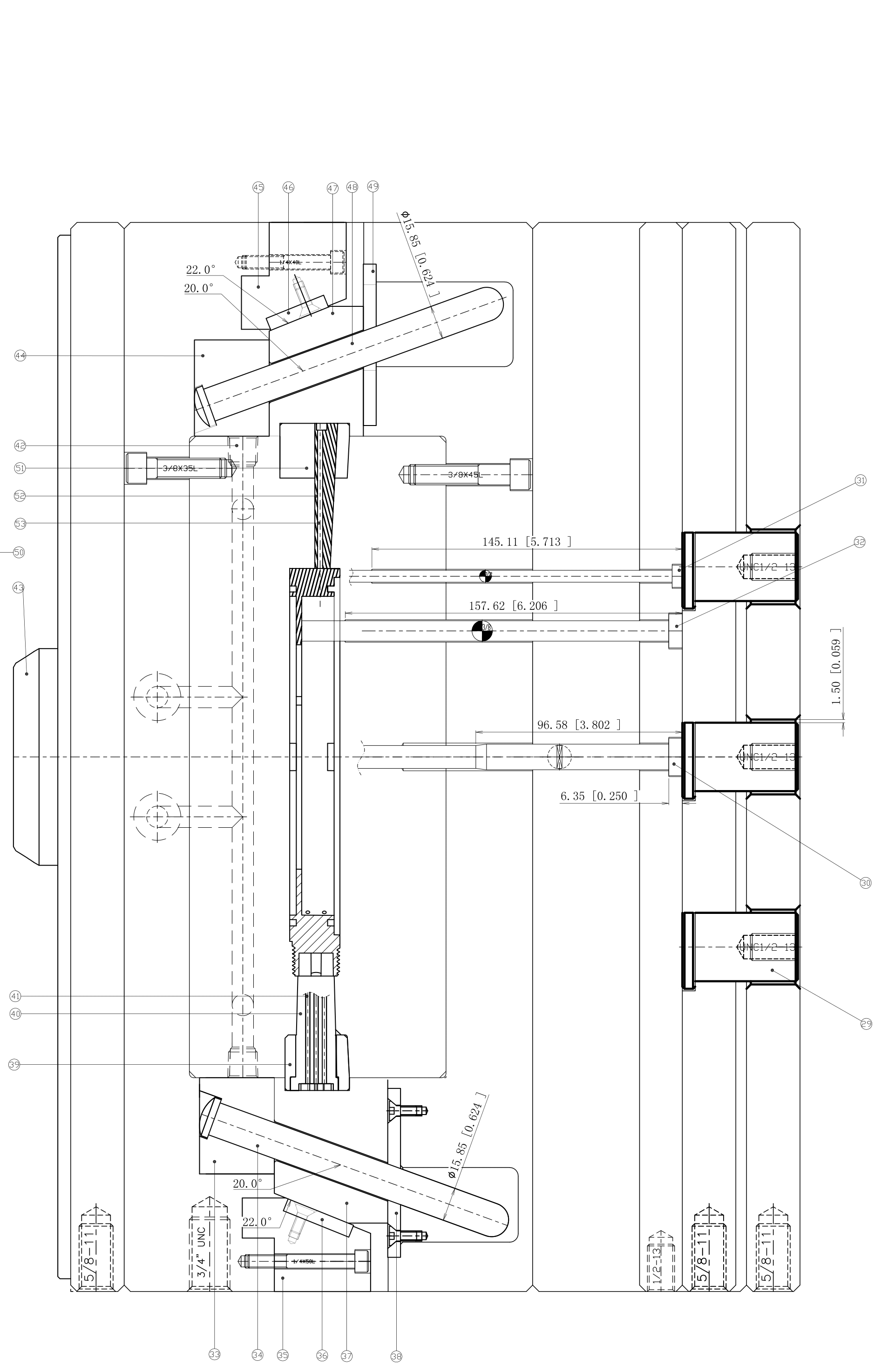

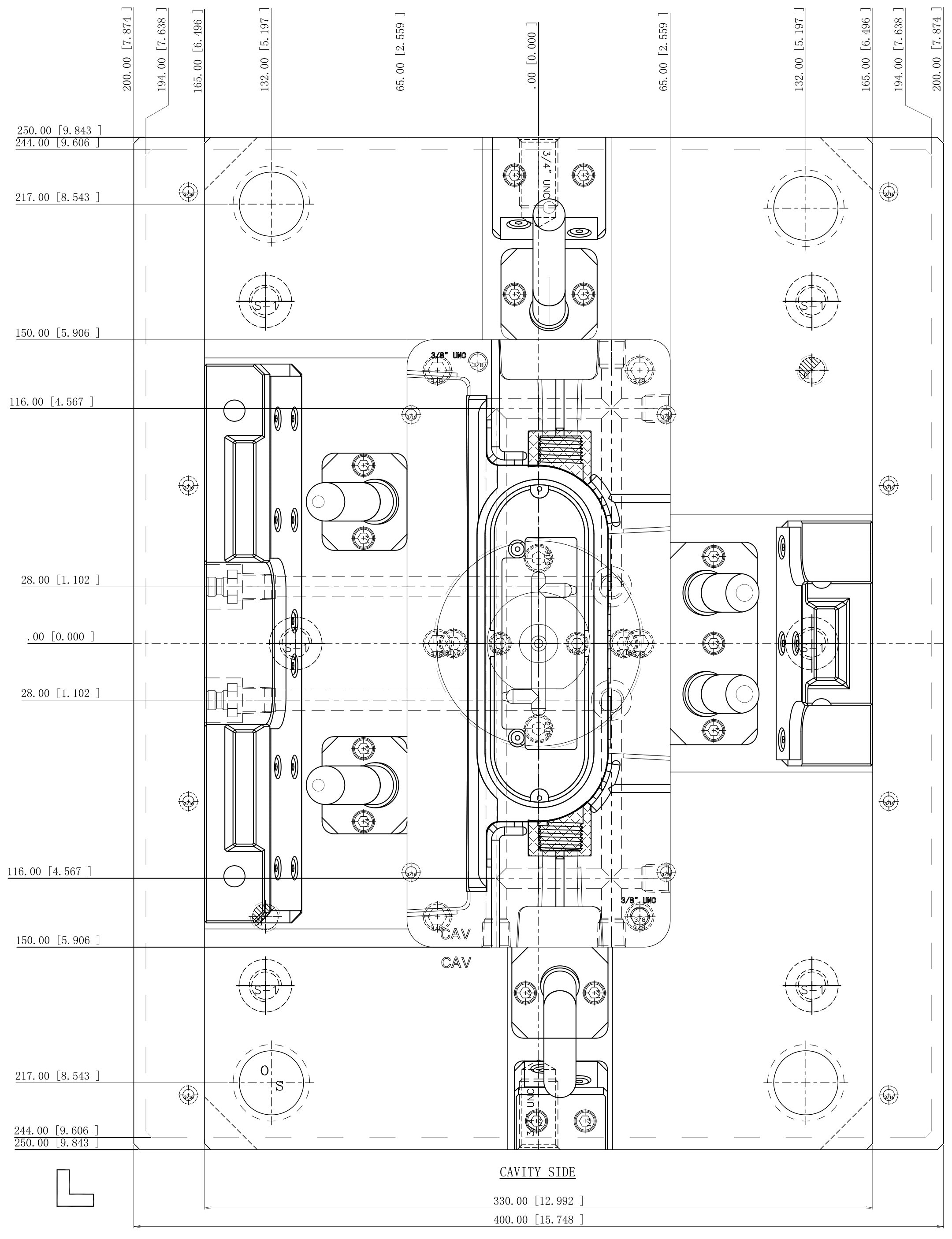

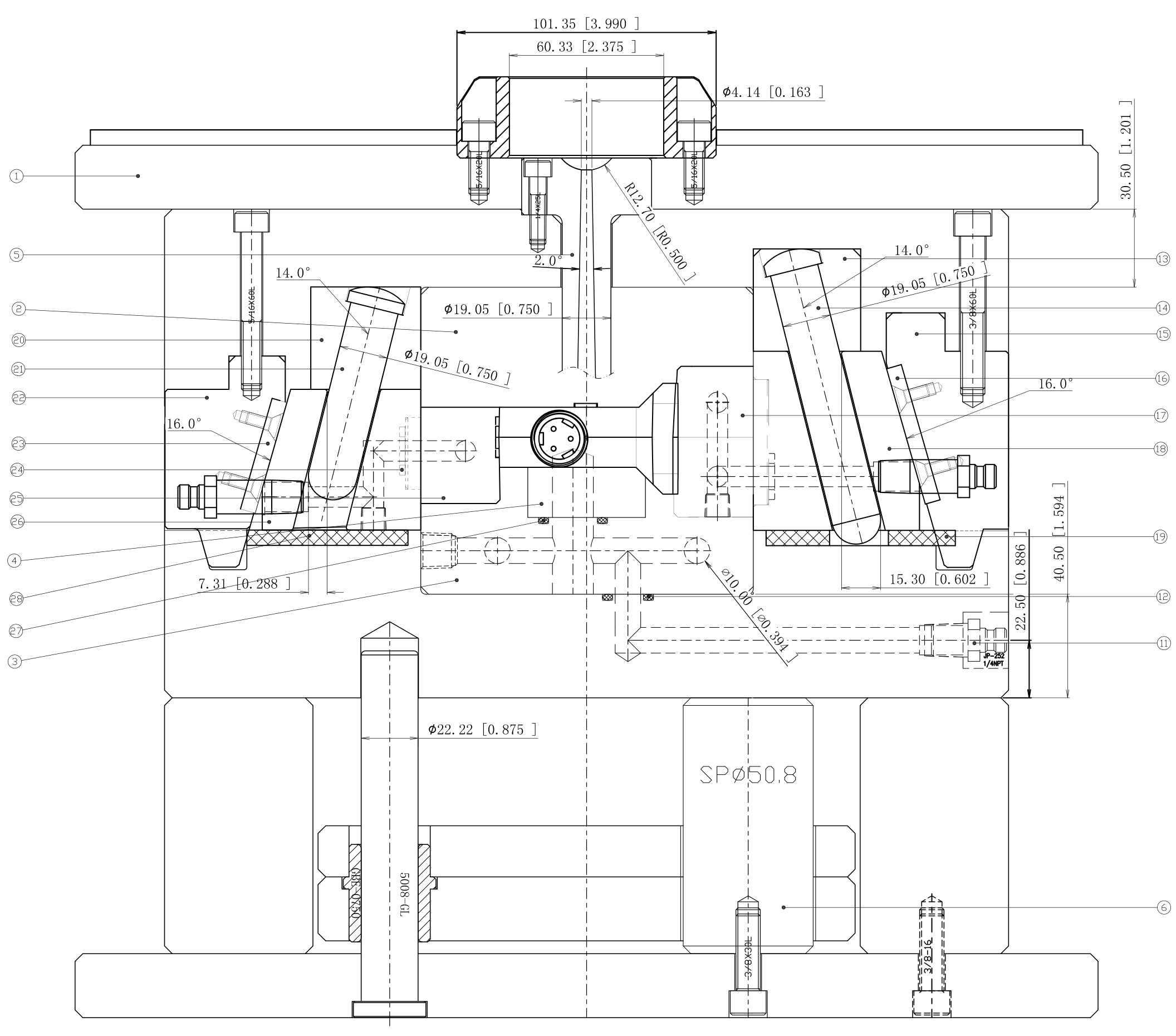

| Design & Concept Consulting Capabilities | Manufacturability Moldability Material Selection |

| Prototyping Capabilities |

3D Printing Machining |

| Rapid Tooling Materials | Aluminum Tool Steel |

| Rapid Tooling Turn Around Time (Aluminum) | 3 to 4 Weeks Rush Service Available |

| Testing & Inspection Capabilities |

Testing: Inspection:

|

| Efficiency |

Six Sigma Certification

Lights Out Manufacturing |

| Secondary Services |

Drilling

Pad Printing |

| Industry Focus |

Aerospace

Marine

Military/Government |

| Industry Standards | Woman Owned Business ASTM American Society for Testing and Materials ISO International Organization for Standardization (Compliant) Mil-Spec Military Specifications RoHS Restriction Of Hazardous Substances (Compliant) UL Underwriters Laboratories |

| File Formats | BMP Bit Mapped Graphics DXF Drawing Interchange Format, or Drawing Exchange Format GIF Graphics Interchange Format IGES (Preferred) Initial Graphics Exchange Specification, ANSI file format. JPG or JEPG Joint Photographic Experts Group Portable Document Format STEP (Preferred) TIFF Tagged Image File Format Unigraphics (PRT) |

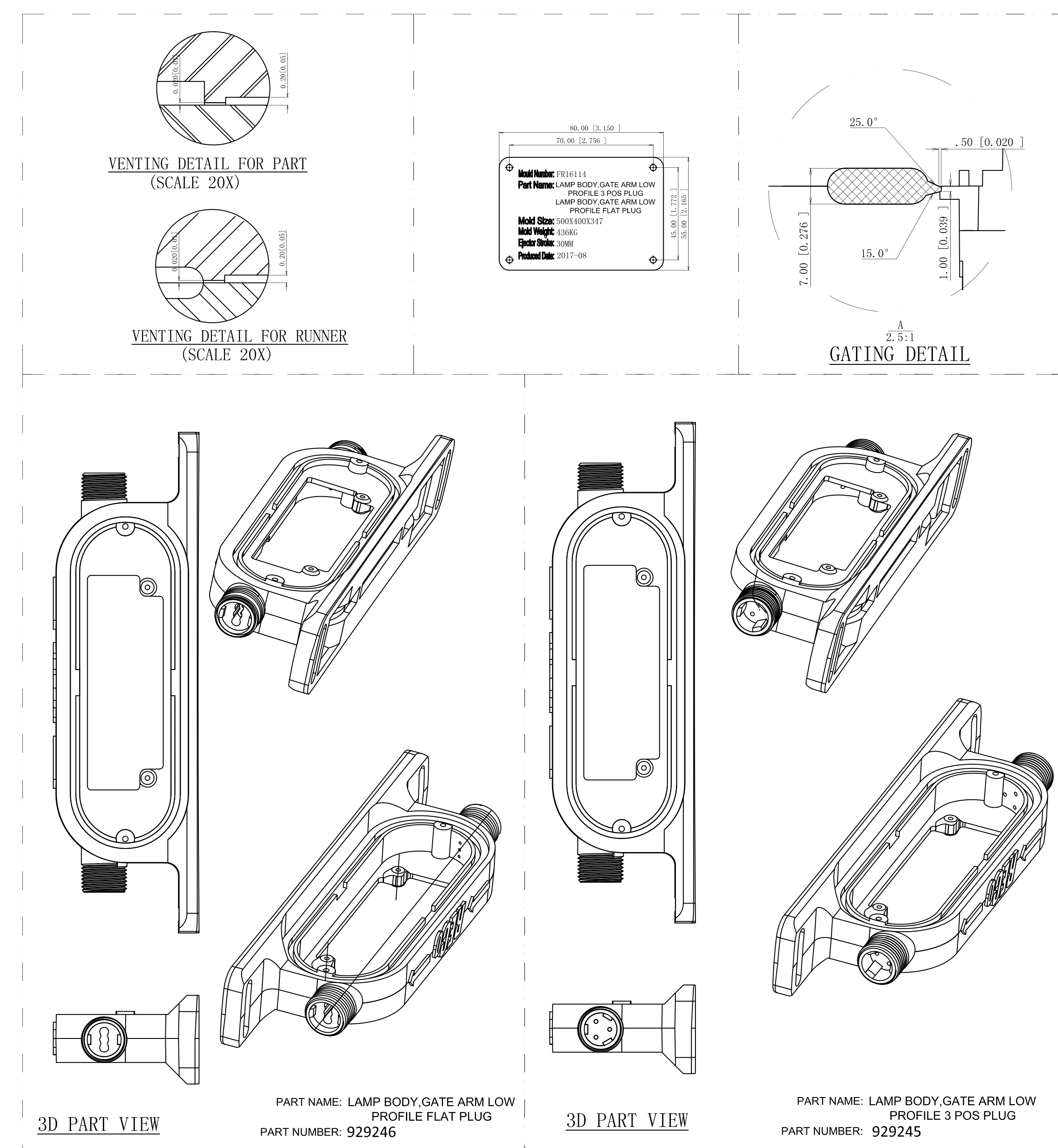

Prototyping Capabilities for Molding - 3D Printing

Prototyping mold making through 3D printing capabilities has revolutionized the traditional approach to mold fabrication, offering a streamlined and efficient process. Leveraging cutting-edge technology, such as the advanced capabilities provided by Harbor Plastics, allows for the rapid development of intricate and precise molds. With 3D printing, intricate geometries and complex designs can be translated into functional molds with unprecedented speed and accuracy. Harbor Plastics' mold building services highlight the integration of state-of-the-art 3D printing technologies, enabling the creation of prototypes that significantly reduce lead times and costs associated with traditional mold making. This innovative approach ensures a seamless transition from concept to production, empowering manufacturers to refine and perfect their designs before committing to large-scale manufacturing.

©2025 Harbor Plastics, Inc. | All Rights Reserved | Privacy Policy | Site Map - Industrial Web Design by WYSIWYG Marketing