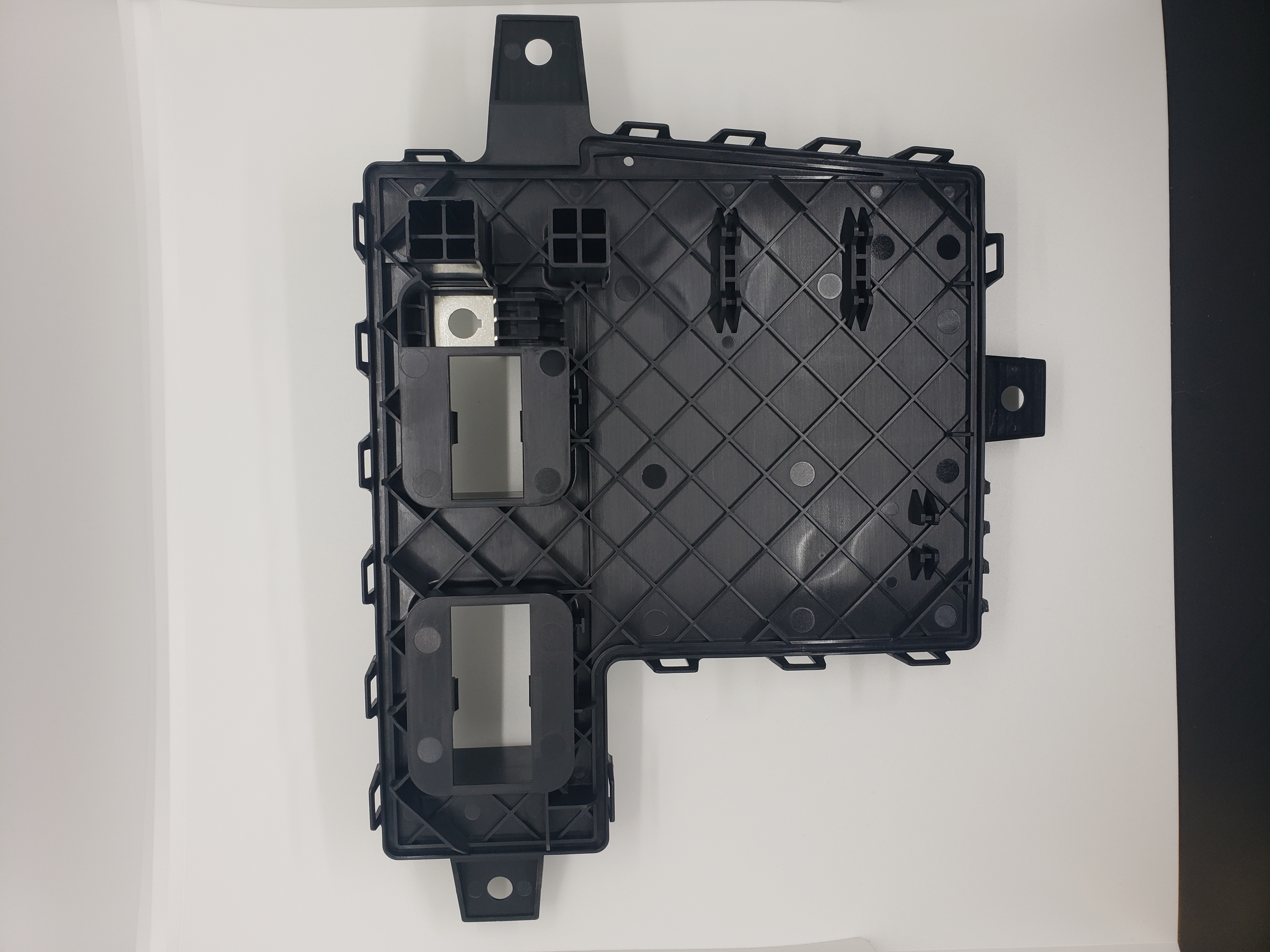

Harbor Plastics, is woman owned company that produces custom plastic injection molding components. We are located in Maple Plain, Minnesota just 15 miles West of Minneapolis.

Our success and plans for growth are based on the recognition that our investment in new manufacturing equipment, technologies and innovative use of computers in design must be coupled with investments in programs that preserve quality relationships with our customers.

This, in turn, results in increased company service and productivity. Our commitment is to deliver value in our products and services that make customers more competitive by enhancing their activities and helping them control costs.

Harbor Plastics takes a systems engineering approach to our business. We know that a successful relationship is based on more than the sale of machine time. Harbor Plastic's very existence is based on meeting and exceeding our customer's expectations the first time. Our personnel are highly qualified in plastic injection molding components. Each and every one of our people are dedicated, experienced and have positive attitudes to our customer's and the work we do for them.

Our customer knows that we stay on budget and on time. From concept to completion you can count on Harbor Plastic to do the best job the industry has to offer.